GCL Technology, one of China’s largest solar panel materials producers, will invest 700 million yuan (US$98 million) to transition to a more lucrative next-generation technology, as the industry grapples with losses and oversupply.

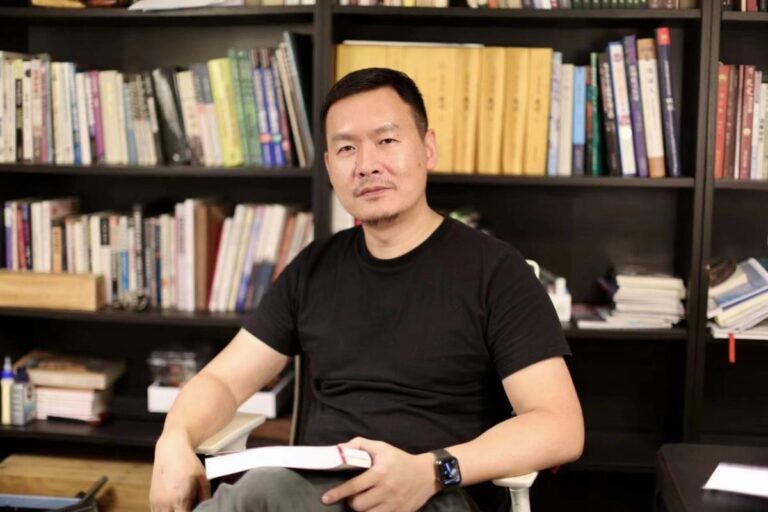

The Hong Kong-listed company aims to complete by the middle of next year the first phase of a 500 megawatt (MW) plant in Kunshan, a city in eastern Jiangsu province near Shanghai, for solar modules that combine cells stacked with perovskite and crystalline silicon, said Fan Bin, chairman of GCL Perovskite.

“The value of the [nascent] perovskite technology lies in the ample room for uplifting its energy conversion efficiency,” he said. “That is why manufacturers are willing to invest in its development.” The future cost of production using the perovskite-silicon technology could be lower than the crystalline silicon technology, he added.

Do you have questions about the biggest topics and trends from around the world? Get the answers with SCMP Knowledge, our new platform of curated content with explainers, FAQs, analyses and infographics brought to you by our award-winning team.

The Suzhou, Jiangsu-based unit will spend 500 million yuan on the equipment and 200 million yuan to fit out a factory with dust-free clean rooms. A second line of the same capacity will be added later.

Fan co-founded the entity in 2013 to commercialise the technology. GCL Tech bought more than 40 per cent of the firm in 2017, giving it a controlling stake.

GCL has signed agreements with prospective customers for the output from the new production line, including China Huaneng Group, State Power Investment Corp and Hong Kong and China Gas (Towngas), Fan said. It is also in talks with some potential overseas partners.

Fan Bin, the chairman of GCL Perovskite. Photo: Handout alt=Fan Bin, the chairman of GCL Perovskite. Photo: Handout

GCL’s perovskite-silicon product has passed efficiency stability tests by certification provider TUV Rheinland, based on the same parameters as crystalline silicon products, he said. It could take two to three years for customers to gain confidence in the new technology, he added.

Most players in the solar industry chain, such as makers of silicon, polysilicon, wafers, cells and modules, are incurring losses because of severe overcapacity.

Fan said the main reason for that is because conventional crystalline technology has only slightly improved the efficiency of converting sunlight to electricity by 0.1 percentage point annually on average since 2017 to 27.3 per cent at present.

“This means new entrants can churn out products almost as good as those of the leaders simply by buying production equipment in the market, which encourages price-based competition through aggressive capacity expansion,” he said.

The theoretical upper limit of energy conversion efficiency of silicon solar cells is 29.4 per cent, against 43 per cent for the new perovskite-crystalline silicon technology, according to Xian-based wafers and…

Read More: China’s GCL investing US$98 million in next-generation solar technology to